4.3 Brake wear testing

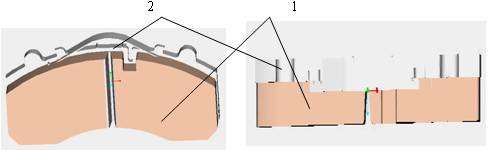

Pad:

The figure 1 in blue is friction material; the figure 2 in white is steel back.

Permitted wear limit=steel back thickness + residual friction material thickness (minimum 2mm)

The thickness of the new pad: 30mm

Permitted wear limit : 12mm

Relative requirements for pad using:

- If there is burn/ polish/crack / oil stain on either side of the friction material of the pad, it should be changed immediately;

- The pad and the pad retainer should be replaced at the same time;

- The pads on the same axle should be replaced at the same time.

Disc: Testing procedure

According to the requirement of part 4.2, measure the thickness of the disc after removing the inner and outer pads.

The initial thickness A of the disc : 45mm

The limit thickness B : 37mm

Jumping Scope : 0.15mm

Maximum thickness gap : 1mm

Disc crack inspection:

A1=crack permitted

B1=maximum radiate crack 0.5mm wide permitted

C1=unevenness less than 1.5 mm permitted

D1=radial through crack surface non- permitted

a=working friction surface

Caution:

- excessive wear of the friction and disc will lead to failure of braking;

- The discs on the same axle should be changed simultaneously. After replacing the new disc, it is recommended to assemble the new pad.