4.2 Clearance automatic adjustment mechanism test

Clearance check:

park the vehicle safely and properly, remove the wheel, push the caliper out along the wheel till it can not move, use the clearance gauge to check the clearance between the outer pad and disc. The normal clearance is 0.7mm-1.2mm. If the practical clearance is not in the normal range, the clearance adjustment mechanism needs to be maintained and adjusted.

Clearance adjuster test: Working(Operating) process

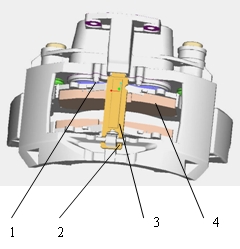

- Take pin 2 away, remove the pad retainer 3 and wear indicator fixed frame ,move the caliper and take off the inner pad 4;

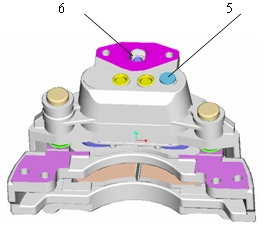

- Take off the adjuster cap 5 on the head of the brake(caliper);

- Use the ratchet spanner to turn the hexagonal M8 clockwise which can adjust the clearance. The plate 1 should extend out while pushing;

Turn the hexagonal M8 anti-clockwise. If the plate 1 could be receded while pushing, that means the transmission chain of the adjuster is normal. If the push plate can not be extended or receded, that means the adjuster is failure, then replace the adjuster or the brake;

- Based on the step 3, push the lever 6, observe the movement of the hexagonal M8:

- the hexagonal M8 does not move at all;

- rotation amount of the hexagonal M8 can not increase with the raise of the rotation angle of lever 6, which means failure of certain parts of the adjuster, and some parts of the adjuster or the adjuster should be replaced;

After testing and maintenance, the brake should be reassembled to ensure its initial state.

Caution:

- The purpose of taking off inner pad 4 is to leave room for inspecting the adjuster

- Only use the ratchet spanner to adjust the hexagonal M8, don’t adjust the hexagonal forcefully.